Straight Quick Connector

The straight connector is small and smart in appearance, streamlined, and saves installation space. The straight connector contains two inner and outer hexagons, which is more convenient for product installation. It has high pressure resistance, temperature resistance and high pressure resistance, and the bursting pressure can reach 5Mpa.

Product Content Introduction

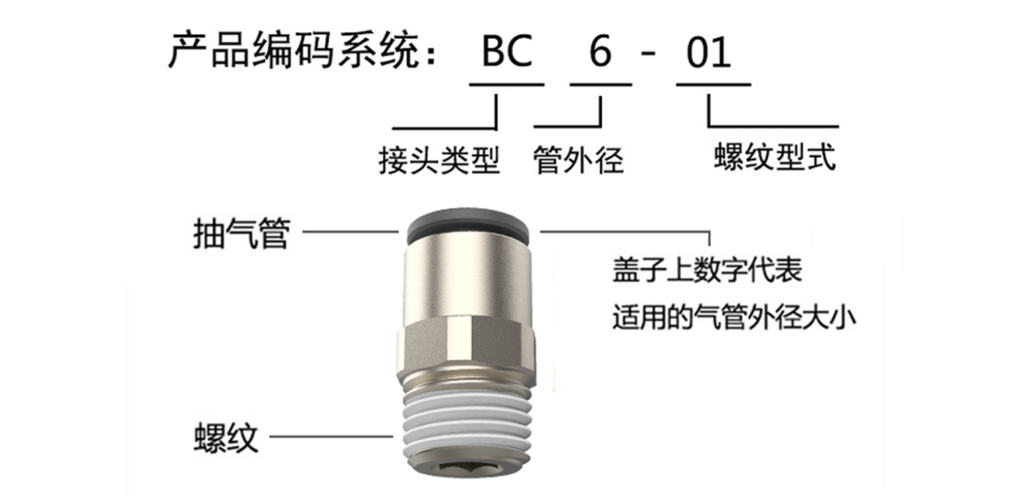

The size of our straight-through quick connector is relatively small compared to other straight-through connectors. Its appearance, excellent adjustment function and diversified adjustment methods are very suitable for general pneumatic applications. The two hexagons inside and outside not only reduce the pressure relief connection, but also meet the installation requirements of different angles. This product is coded BC6-01, BC is the connector type, 6 is the outer diameter of the pipe, and 01 is the thread type. The number on the product cover represents the outer diameter of the applicable air pipe.

Product Features:

(1) The appearance is small and smart, and the overall shape is streamlined, saving installation space.

(2) Positive and negative pressure are the same, and it is more suitable for vacuum equipment to reduce pressure release and achieve energy saving.

(3) The threaded straight-through quick-connect connector has two inner and outer hexagons, which makes it easier to install the product.

(4) The pipe and the joint body can be rotated 360° without damaging the pipe, which is suitable for installation requirements at different angles.

(2) Positive and negative pressure are the same, and it is more suitable for vacuum equipment to reduce pressure release and achieve energy saving.

(3) The threaded straight-through quick-connect connector has two inner and outer hexagons, which makes it easier to install the product.

(4) The pipe and the joint body can be rotated 360° without damaging the pipe, which is suitable for installation requirements at different angles.

Specifications:

Scope of Application:

Compressed air, vacuum, water

Vacuum Capacity:

755mmHg (99% vacuum)

Operating Temperature:

-20~+60℃

Work Pressure:

When the working temperature is 0~10℃, the maximum is 15Bar. The maximum working pressure is related to the type of plastic pipe used.

Materials Used:

Engineering plastics, nickel-plated brass, nitrile rubber, stainless steel

Model:

BC

Working temperature:

-20℃/+60℃

Maximum operating pressure:

15 Bar

Material:

nickel-plated brass, engineering plastics, nitrile rubber

Applicable media:

compressed air, vacuum, water

Vacuum rated pressure:

755 mmHg (99% vacuum)

Suitable for pipe outer diameter: Ø4, Ø6, Ø8, Ø10, Ø12, Ø1/8, Ø5/32, Ø1/4, Ø5/16, Ø3/8, Ø1/2

Connection thread: R1/8, R1/4, R3/8, R1/2, 10-5/32, NPT1/8, NPT1/4, NPT3/8, NPT1/2

Precautions for using trachea pneumatic joints:

1. Make sure that the cut surface of the pipe is vertical, there are no scratches on the outer circumference of the pipe, and the pipe is not oval.

2. When inserting the pipe, be sure to insert it to the bottom of the joint. If the pipe is not inserted to the bottom, it may cause leakage.

3. After the pipes are connected, pull the pipes to make sure that the pipes cannot be pulled out of the joints.

4. Please do not use for purposes other than fluids.

5. Do not exceed the maximum operating pressure during use.

6. Do not use it outside the operating temperature range to prevent deformation of the sealing material, which may cause leakage.

7. Do not hit, bend or stretch it artificially to prevent damage.

8. Do not use in places mixed with metal powder or sand dust, as attachment of debris may cause malfunction or leakage.

2. When inserting the pipe, be sure to insert it to the bottom of the joint. If the pipe is not inserted to the bottom, it may cause leakage.

3. After the pipes are connected, pull the pipes to make sure that the pipes cannot be pulled out of the joints.

4. Please do not use for purposes other than fluids.

5. Do not exceed the maximum operating pressure during use.

6. Do not use it outside the operating temperature range to prevent deformation of the sealing material, which may cause leakage.

7. Do not hit, bend or stretch it artificially to prevent damage.

8. Do not use in places mixed with metal powder or sand dust, as attachment of debris may cause malfunction or leakage.

Notes when disassembling:

1. Use appropriate tools to disassemble the pipe joint using the outer hexagonal part of the pipe joint.

2. Remove the sealing material adhering to the opposite side of the pipe joint to prevent the adhering sealing material from entering the surrounding components and causing failure.

2. Remove the sealing material adhering to the opposite side of the pipe joint to prevent the adhering sealing material from entering the surrounding components and causing failure.