L-type quick connector

PL right-angle quick connector, elbow connector, L-type quick connector, adopt oval release ring, good sealing performance, plastic parts can be rotated 360°, easy to install and use at different angles, reliable quality, greatly enhanced pressure resistance.

Product Content

Product Application:

(1) The quick-connect air pipe connection is used to conduct compressed air.

(2) It has various uses depending on the user environment.

(2) It has various uses depending on the user environment.

Features:

(1) PL right angle quick-connect fittings, elbow fittings, L-type couplings.

(2) The oval release ring makes disassembly easier and more labor-saving.

(3) The threads of the vascular pipes are pre-coated with polytetrafluoroethylene anti-leakage glue, which has good sealing performance.

(4) The plastic parts can be rotated 360°, which is convenient for installation and use at different angles.

(5) The compression spring has a greater gripping force, is not easy to fall out, and can work better.

(6) Zinc alloy spring sleeve, reliable quality and pressure resistance, greatly enhanced pressure resistance.

(7) High-quality sealing ring to prevent gas leakage.

(2) The oval release ring makes disassembly easier and more labor-saving.

(3) The threads of the vascular pipes are pre-coated with polytetrafluoroethylene anti-leakage glue, which has good sealing performance.

(4) The plastic parts can be rotated 360°, which is convenient for installation and use at different angles.

(5) The compression spring has a greater gripping force, is not easy to fall out, and can work better.

(6) Zinc alloy spring sleeve, reliable quality and pressure resistance, greatly enhanced pressure resistance.

(7) High-quality sealing ring to prevent gas leakage.

Scope of use:

Scope of application

Compressed air, water

Work Pressure

0-150PSI / 0-9.9kgf/cm² (0~990kPa)

Negative pressure

-29.5inHg / -750mmHg (-750Torr)

Operating temperature

32-140°F / 0-60°C

Using a trachea

Polyurethane and nylon tubing

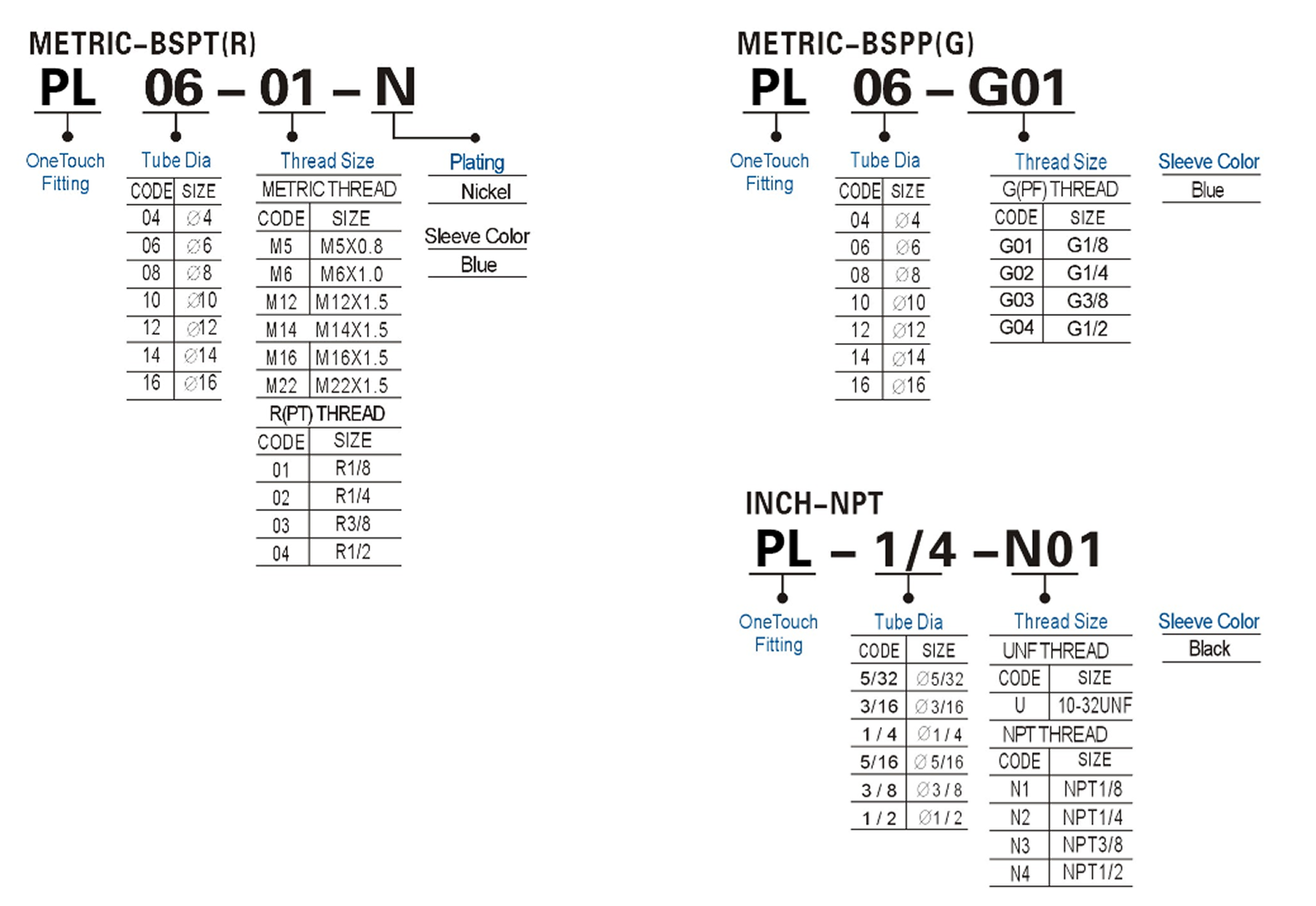

Coding system:

Model:

PL

Working temperature:

0℃/+60℃

Maximum operating pressure:

990 kPa

Material:

nickel-plated brass, PBT, NBR, stainless steel

Applicable medium:

compressed air, water

Use air tube:

polyurethane and nylon air tube

Suitable for pipe outer diameter: Ø4, Ø6, Ø8, Ø10, Ø12, Ø1/8, Ø5/32, Ø1/4, Ø5/16, Ø3/8, Ø1/2

Connection thread: R1/8, R1/4, R3/8, R1/2, 10-5/32, NPT1/8, NPT1/4, NPT3/8, NPT1/2

Precautions for using trachea pneumatic joints:

1. Before use, be sure to refer to the safety precautions, warning display classifications and general precautions for pipe fittings.

2. When inserting the pipe, be sure to insert it to the bottom of the joint. If the pipe is not inserted to the bottom, it may cause leakage.

3. After the pipes are connected, pull the pipes to make sure that the pipes cannot be pulled out of the joints.

4. Please do not use for purposes other than fluids.

5. Do not exceed the maximum operating pressure during use.

6. Do not use it outside the operating temperature range to prevent deformation of the sealing material, which may cause leakage.

7. Do not hit, bend or stretch it artificially to prevent damage.

8. Do not use in places mixed with metal powder or sand dust, as attachment of debris may cause malfunction or leakage.

2. When inserting the pipe, be sure to insert it to the bottom of the joint. If the pipe is not inserted to the bottom, it may cause leakage.

3. After the pipes are connected, pull the pipes to make sure that the pipes cannot be pulled out of the joints.

4. Please do not use for purposes other than fluids.

5. Do not exceed the maximum operating pressure during use.

6. Do not use it outside the operating temperature range to prevent deformation of the sealing material, which may cause leakage.

7. Do not hit, bend or stretch it artificially to prevent damage.

8. Do not use in places mixed with metal powder or sand dust, as attachment of debris may cause malfunction or leakage.

Notes when disassembling:

1. Use appropriate tools to disassemble the pipe joint using the outer hexagonal part of the pipe joint.

2. Remove the sealing material adhering to the opposite side of the pipe joint to prevent the adhering sealing material from entering the surrounding components and causing failure.

2. Remove the sealing material adhering to the opposite side of the pipe joint to prevent the adhering sealing material from entering the surrounding components and causing failure.