Extended L-elbow

Our PLL extended threaded elbow has an extended threaded part, which is suitable for use in special environments. The product has stable performance and high cost performance.

Product Content

Product Application:

(1) The quick-connect air pipe connection is used to conduct compressed air.

(2) It has various uses depending on the user environment.

(2) It has various uses depending on the user environment.

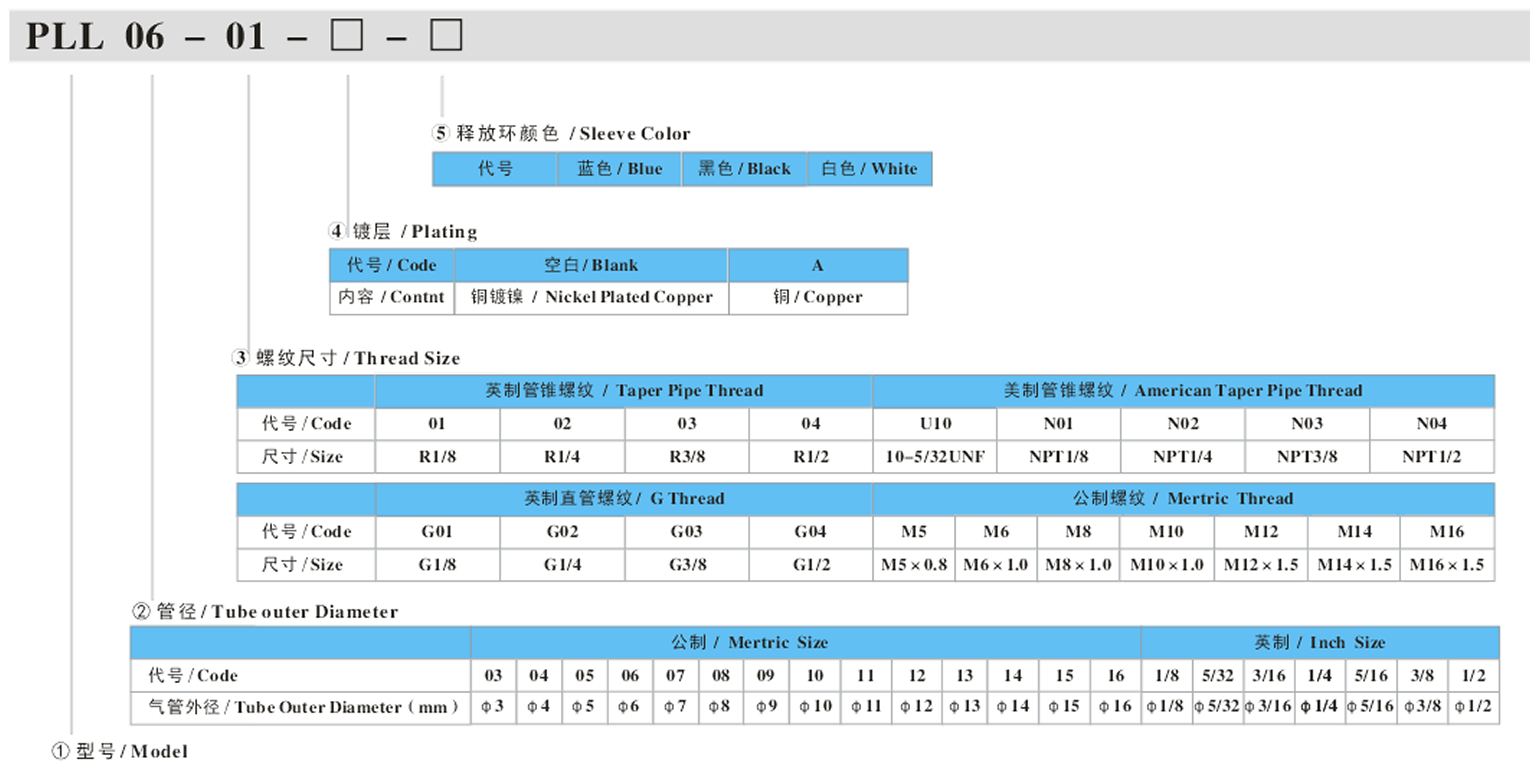

Coding system:

Features:

(1) Extended thread elbow, the thread part is extended, suitable for use in special environments.

(2) The threaded part is lengthened, but the size and thread of the insert are the same as the conventional ones, which is suitable for installation in special spaces.

(3) Made of high-quality copper rods, the electrolytic nickel plating process makes it hard, corrosion-resistant and not easy to oxidize.

(4) No loosening or leakage, precise size, pressure resistance and no stripping, reliable installation and good sealing.

(5) The threaded part is coated with sealant and the M5 metric thread is equipped with a sealing gasket to ensure that there is no leakage in the threaded connection part.

(6) Tighten the high-quality retaining ring to firmly clamp the air pipe to prevent it from falling off.

(2) The threaded part is lengthened, but the size and thread of the insert are the same as the conventional ones, which is suitable for installation in special spaces.

(3) Made of high-quality copper rods, the electrolytic nickel plating process makes it hard, corrosion-resistant and not easy to oxidize.

(4) No loosening or leakage, precise size, pressure resistance and no stripping, reliable installation and good sealing.

(5) The threaded part is coated with sealant and the M5 metric thread is equipped with a sealing gasket to ensure that there is no leakage in the threaded connection part.

(6) Tighten the high-quality retaining ring to firmly clamp the air pipe to prevent it from falling off.

Product Details:

Model: PLL

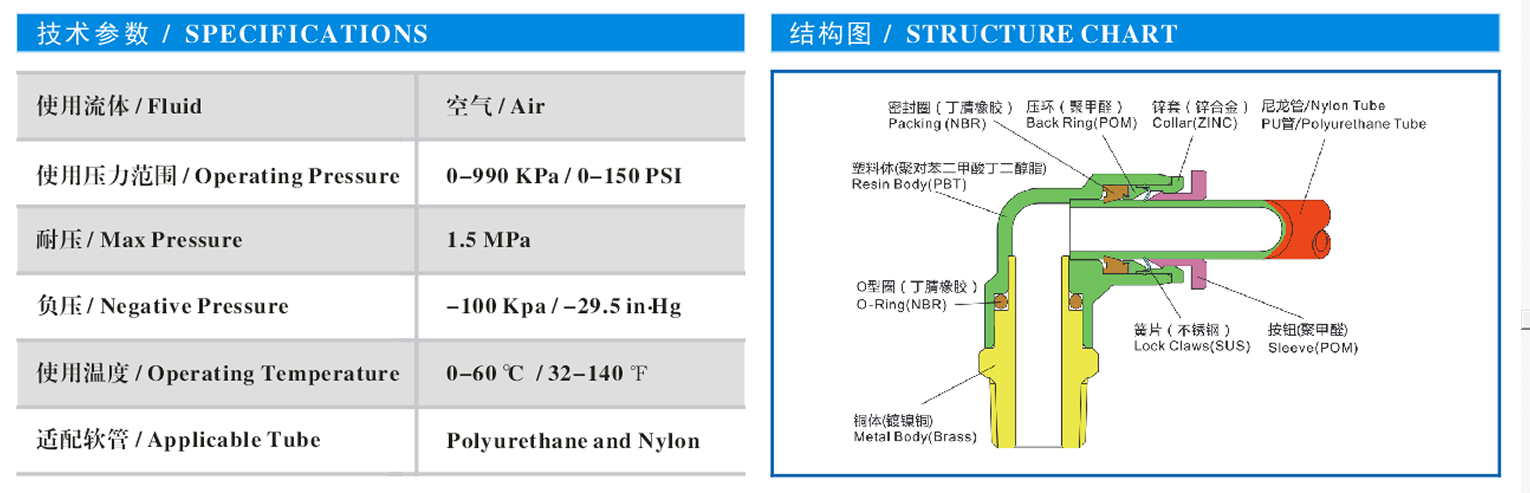

Working temperature:

0℃/+60℃

Maximum operating pressure:

990 kPa

Material:

nickel-plated brass, PBT, NBR, stainless steel

Applicable medium:

compressed air, water

Use air tube:

polyurethane and nylon air tube

Suitable for pipe outer diameter: Ø4, Ø6, Ø8, Ø10, Ø12, Ø14, Ø16, Ø1/8, Ø5/32, Ø3/8, Ø1/4, Ø5/16, Ø3/8, Ø1/2

Connection thread: R1/8, R1/4, R3/8, R1/2, 10-5/32, NPT1/8, NPT1/4, NPT3/8, NPT1/2, M3, M5, M7, M8, M10, M12

Precautions for using trachea pneumatic joints:

1. Before use, be sure to refer to the safety precautions, warning display classifications and general precautions for pipe fittings.

2. When inserting the pipe, be sure to insert it to the bottom of the joint. If the pipe is not inserted to the bottom, it may cause leakage.

3. After the pipes are connected, pull the pipes to make sure that the pipes cannot be pulled out of the joints.

4. Please do not use for purposes other than fluids.

5. Do not exceed the maximum operating pressure during use.

6. Do not use it outside the operating temperature range to prevent deformation of the sealing material, which may cause leakage.

7. Do not hit, bend or stretch it artificially to prevent damage.

8. Do not use in places mixed with metal powder or sand dust, as attachment of debris may cause malfunction or leakage.

2. When inserting the pipe, be sure to insert it to the bottom of the joint. If the pipe is not inserted to the bottom, it may cause leakage.

3. After the pipes are connected, pull the pipes to make sure that the pipes cannot be pulled out of the joints.

4. Please do not use for purposes other than fluids.

5. Do not exceed the maximum operating pressure during use.

6. Do not use it outside the operating temperature range to prevent deformation of the sealing material, which may cause leakage.

7. Do not hit, bend or stretch it artificially to prevent damage.

8. Do not use in places mixed with metal powder or sand dust, as attachment of debris may cause malfunction or leakage.

Notes when disassembling:

1. Use appropriate tools to disassemble the pipe joint using the outer hexagonal part of the pipe joint.

2. Remove the sealing material adhering to the opposite side of the pipe joint to prevent the adhering sealing material from entering the surrounding components and causing failure.

2. Remove the sealing material adhering to the opposite side of the pipe joint to prevent the adhering sealing material from entering the surrounding components and causing failure.